Rotron

Services

Engine Design

Rotron is able to rapidly design and develop bespoke engines to meet your required performance needs and characteristics.

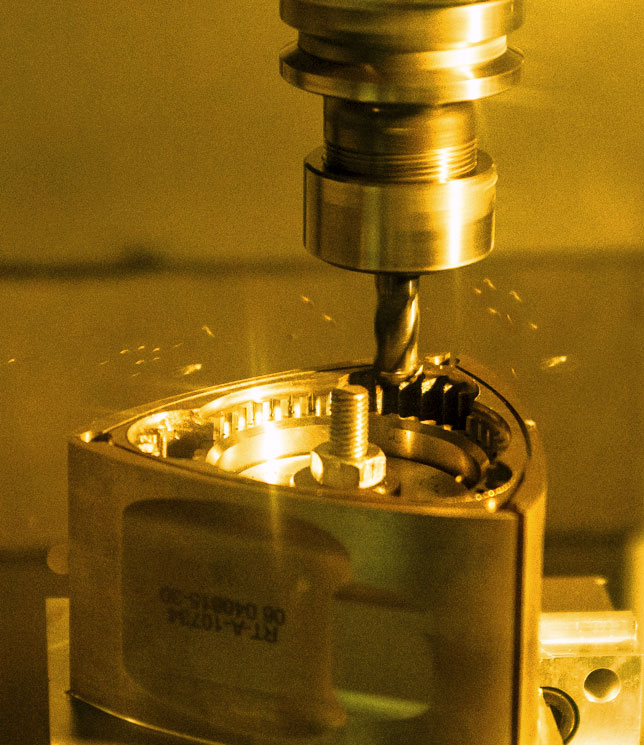

DETAILSEngine Manufacture

Experience in design for manufacture and production engineering ensures efficiency, consistency and high-quality standards.

DETAILSEngine Testing

Our capabilities range from sub-zero thermal shock and high elevation temperatures, through to endurance.

DETAILSSystem Integration

Our integration services are the key to optimal rotary engine technology solutions that support your propulsion needs.

DETAILSTechnical Support

Rotron provides a full or partial technical support service on all our engines, ensuring client piece of mind when out in the field.

DETAILSLogistics

Our logistical support network allows us to deliver engines worldwide - quickly, cost effectively and in operation-ready condition.

DETAILSFrom the moment our engines leave the factory our primary mission begins; providing the services and support to carry out operations efficiently and cost-effectively.

Rotron provides manufacturers and operators with the experience, resource and technical support for a rapid and effective response they need to keep their platforms operational and mission-ready. Working in partnership to understand operational and organisational needs, our services are customised and continuously adapted to provide the most cost-effective through-life support.

Engine Design

With great design,

comes great engineering

Engine Manufacture

Bringing rotary engines

to life and to market

Engine Testing

A critical role in our

engine development

System Integration

Optimised around the

needs of the customer.

Technical Support

The ability to focus

on core operations

Logistics